Electronic and power electronic systems place very different demands on their electrical, mechanical and thermal connection and protection against adverse environmental influences.

With our multidisciplinary team and an air-conditioned machining centre with extensive machinery, we can develop practical solutions and manufacture up to small series. We keep an eye on the system and develop economical packaging concepts.

We offer this comprehensive service to our partner institutes at KIT, large-scale research projects of the Helmholtz Association and industrial customers.

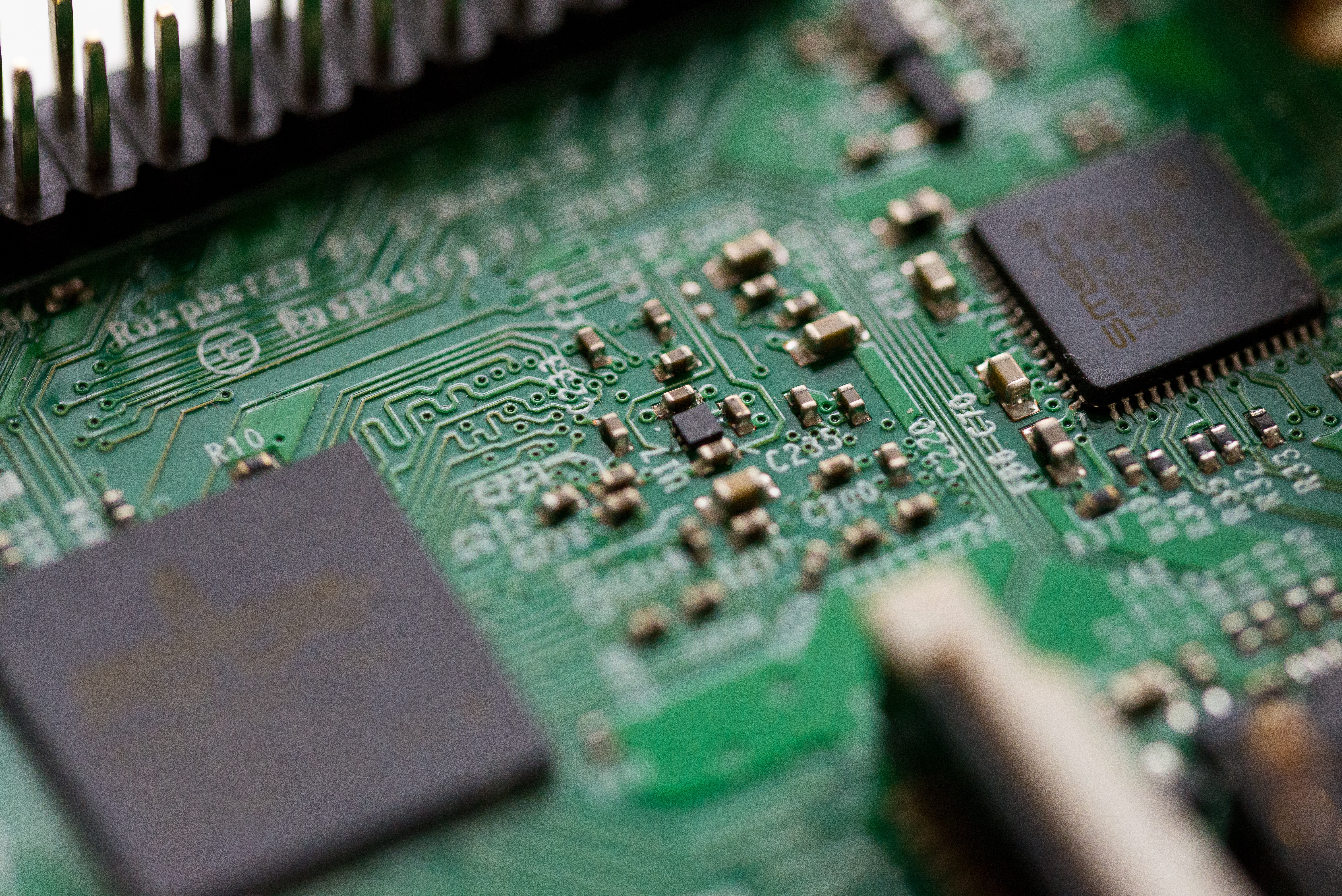

Our research focuses on the field of power electronic module technology and increasing the lifetime of power electronic systems. In addition to the classic DCB substrates, we are working on making the thick film technology common in hybrid technology advantageously usable for highly integrated power modules. Within the framework of cooperative projects, we are also involved in the development of battery management systems and systems in the field of electromobility and renewable energies.

The focus of our work lies in the following areas

Circuit technology: circuit and layout development, especially for battery management systems and electrical measurement technology

Production technology: Thick film technology and soldering and bonding processes for hybrid assemblies, PCB design and assembly

Measurement and characterization: shear and hook test for wire bonds, characterization of power electronic modules

Life cycle investigations: Climate cabinet and load cycle testing, especially of power electronic modules

power electronic systems: Inverter concepts for photovoltaic and motor operation