Our research area includes battery management systems (BMS), cooling concepts, interconnection technologies and much more.

Dynamically reconfigurable battery systems

In the future, battery storage systems will play a key role in the energy grid and in mobility. Integrated power electronic components allow dynamically reconfigurable battery systems to change their topology during runtime, which significantly increases the safety and availability of the system. In addition, different battery technologies can be combined to meet special requirements.

Modular Multilevel Battery System (MMBS)

Similar to the dynamically reconfigurable battery system described above, the Modular Multilevel Battery System (MMBS) can also be flexibly reconfigured. The special feature, however, is that not only the arrangement of individual modules can be changed, but each individual battery cell in the serial connection can optionally be bridged or added to the stack in positive or negative polarity. Since this reconfiguration is controlled by power electronic switches and can take place in the kilohertz range, the MMBS can output sinusoidal voltages without additional converters or even directly drive three-phase machines by connecting several modules in parallel. Due to the fine granular generation of different discrete voltage levels, the switching losses are reduced enormously compared to conventional converters. In addition, an application-tailored design of the MMBS can eliminate the need for many conventionally required power electronics.

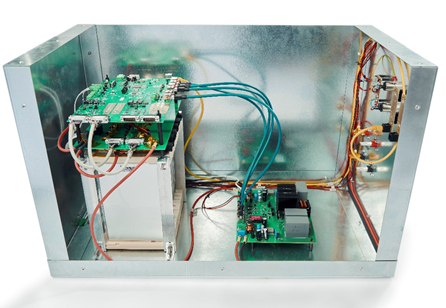

Lithium-ion battery storage systems can store energy efficiently and over a long period of time. In addition, they can deliver or absorb high power very quickly and thus, for example, compensate for short-term disturbances in the grid. For the safe operation of batteries, a reliable battery management system (BMS) is essential, which monitors and evaluates the status of all individual battery cells. In addition to measuring the temperature and voltage of the cells and the current through them, the microcontrollers in the BMS also calculate other parameters. These include, in particular, the state of charge (SoC) as well as the charge and discharge current permitted at the current operating point or data on the aging of the cells. In addition, the BMS also communicates with other devices, such as an inverter or energy management system.

The development of safe battery systems is complex. The digital control systems require reliable development tools. In the area of software development, we therefore work with the development environment and compiler of the TriCore Software Development Toolset of our official sponsor TASKING.